Off-the-shelf solutions don’t always cut it – especially when your application requires safety or ergonomic motion and performance beyond a standard hinge. If you’re trying to support a heavy lid, conveyor drawbridge or enclosure cover, a custom hinge built with motion control in mind is the best fit.

A properly engineered counterbalance hinge can make an 80-pound lid feel like a light 2-pounds when lifting. It’s not magic though – it's precision mechanical engineering using counterbalance spring design principles.

That’s why we allow you to tailor Weber Knapp’s four Vectis counterbalance hinge sizes - to give your project the precise torque it needs. The quickest (and maybe the most fun) way to do this is with the Vectis online app. Using the intuitive app, you can create a custom spring counterbalance hinge in minutes and save it for our engineers to review.

The five steps below show how to design your hinge from start to finish using the app.

Remember: Vectis experts can assist you at any stage of your design. So if this all feels like too much and you need to step back, tag us in!

What Is a Counterbalance Hinge in Mechanical Motion Control?

A counterbalance hinge is a custom mechanical hinge that uses springs and internal linkages to offset the weight of a load – think lids, doors or covers. When you offset the gravitational force that’s acting on the load, these hinges improve safety, ease of use, and reduce mechanical strain.

Our experts use motion control engineering to design hinge systems that allow smooth, effortless movement with no slamming or drop risk. The result? A safer, more ergonomic experience for users in industries where lid or panel control is highly critical.

5 Steps to Build a Custom Hinge With Counterbalance Spring Design

(Watch the video above for a step-by-step walkthrough on using the Vectis app.)

(Watch the video above for a step-by-step walkthrough on using the Vectis app.)

1. Figure out Your Starting Specs

To get started with the Vectis™ DYO app, you’ll need to plug in the three critical parameters of the load to be counterbalanced:

(Note: we use “lid” frequently below, but the same information applies to whatever you’re looking to support, whether that’s a door, cover, or other load.)

Lid Weight

Determining the weight of your lid is simply a matter of removing the entire lid or rotating load, if it already exists, and weighing it using a high-quality scale. Alternatively, a modern CAD system can easily predict both weight and center of gravity within your design quite reliably before your device is even built.

Lid Center of gravity

Here’s where you get the second and third critical stats of your load. For the purposes of the app, we’re referring to the center of gravity when your lid is closed.

The easiest way to find this is to simply send your lid design to us. We have a tried-and-true method in which we take force readings at different angles. We use that information combined with our proprietary software to determine your design’s center of gravity.

We find customers get far better results when we take the measurements ourselves, but we’ve also shown customers how to do it. Or, if you insist on finding the center of gravity yourself, you can try one of the methods here.

The “Distances” in the second and third boxes under Parameters refer to the location of your load’s center of gravity (C.G.) relative to the pivot axis when your load is in the 0° (closed or lowest) position.

2. Choose the Right Vectis Hinge for Your Motion Control Needs

Now let’s set things in motion! Select a Vectis model - 200, 600, 1200, or 1800 - and how many you need. All Vectis counterbalance spring designs allow up to 90° of rotation.

Now let’s set things in motion! Select a Vectis model - 200, 600, 1200, or 1800 - and how many you need. All Vectis counterbalance spring designs allow up to 90° of rotation.

Use the slide bar variables in the app to get the optimum torque curve and fine-tune the open/close feel.

Based on the values entered in Step 1, the Vectis app automatically calculates the approximate torque required to lift your load from its closed position. It displays this value in the Required Torque text box.

The graphic on the right updates as you change parameters so you’re not purchasing anything blindly. You can use the Required Torque value to make an initial guess about which Vectis counterbalance hinge model might be appropriate and how many hinges each lid requires.

3. Determine How Many Industrial Hinges Your Project Needs

A typical lid will require two or more hinges to provide adequate mechanical support that keeps users safe and happy. Occasionally, one hinge will do for a light or narrow load.

You should weigh several factors when deciding on the number of hinges for each lid. These include mounting considerations -- for example, if your hinges must support the middle of an unusually long lid, keep that in mind. Very large lids can require several Vectis hinges just to provide the spring energy needed to counterbalance that weight.

Overview of factors to consider:

- Load size and weight

- Mounting constraints

- Balance points across the lid

Be careful to keep the pivot axis center lines of multiple hinges aligned.

4. Test and Adjust the Motion Control in the App

The orange Spring Torque Curve line on the app’s graph represents the spring-based opening torque applied by your hinges. By inputting or adjusting a few additional parameters on the app, you can position the orange line above, on, or below the black line at different angles. This helps you control the amount of spring-based torque that’ll be applied to counteract your lid at each angle.

The lighter orange lines give you a rough idea of the controlled friction band built into your hinge. There’s a little bit of friction inherent to all hinges. This friction helps hold your load in place. In areas where the black lid torque line is between the light orange lines, the lid or load will stay put.

- Orange curve line = Spring torque.

- Black line = Lid torque.

- Light orange line = Friction zone.

Remember: All inputs are interactive, so changing one value in the app may alter or limit other values. It’s important to evaluate multiple design combinations before choosing the best solution. Experiment!

5. Design the Built-In Open Stop Angle for Better Control

In the Lid “open stop” Angle input box, simply type in the open stop angle desired.

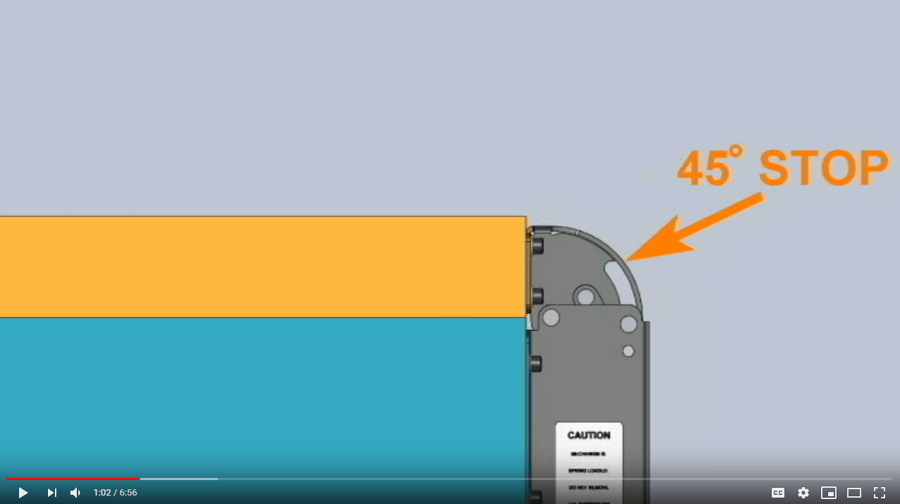

Not all hinge applications require 90° of rotation. You can instead specify an open stop angle between 45° and 90°. This angle will be permanently cut into your hinge when it is manufactured.

This 45° and 90° angle will:

- Prevent over-rotation

- Improve ergonomic positioning

- Allocate spring energy efficiently

There are many situations where a limited angle makes sense. Examples include keeping a lid’s handle within convenient operator range or avoiding obstacles in the area of your rotating load.

You also may wish to prevent an uncontrolled “float open” condition. Limiting pointless movement might allow internal spring resources to be allocated for better counterbalancing in a more critical area of lid rotation.

How Variable A and B Shape Your Hinge's Custom Torque Curve

Variable A and B represent geometry that’ll be permanently cut into the internal linkage of your hinges. The spring settings dictate the initial spring adjustment made at the factory. The unique result of these three numbers tailors your hinge to your needs. The result is reflected on the orange Spring Torque Curve line.

At angles where the spring torque is higher than the lid torque, the lid will self-open. When the spring torque is lower, the lid will self-close.

The built-in open stop is more than capable of withstanding normal spring and static weight loads. However, if you expect high external or inertia-based loads in your application, added external support is a must.

Benefits of Custom Hinges for Motion Control & Safety

When you’re designing a custom hinge system, it gives you complete control, more than just the movement aspect. With proper hinge design and counterbalancing, your system gains:

- Safety: No more drop risks or lid slams, ensuring user safety.

- Ease of use: Heavy lids feel lighter, reducing strain and effort.

- Durability: Less wear means longer product lifespan.

- Ergonomics: Operators lift and move lids with less strain, benefiting user health and comfort.

Custom counterbalance hinges are rock stars in various industries, offering effortless lid opening, safety, ease of use, and product longevity.

Find the Right Mechanical Hinge Design for Your Project

When you’re completely satisfied with your custom-made design, you can register it by providing a project file name, other required information, and your username. Once you’ve saved your design, Weber Knapp will provide you with a screenshot of the torque curve.

(Still struggling to finish your design on the app? This PDF provides additional examples and graphics of how to use it.)

After you’ve finished your design and registered an account, a member of the Weber Knapp team will be in touch via email. This initial contact will include a price quote and a production time estimate.

Create Your Own Hinge Design

If you’re looking for custom spring counterbalance hinges, industrial spring hinges or a scalable motion control solution, the Vectis DYO app can help you find what you need. Ready to design your hinge? Click below to get started.

(Editor's Note: This blog was originally published in July 2019 and was recently updated in July 2025.)

.png?width=12000&height=2033&name=WeberKnappLogo_white%20(1).png)