When trying to include an innovative or safety-minded motion control design in your product, there’s a sneaky-confusing word you should know: torque.

Torque is very important. Generally speaking, it’s nearly impossible to watch an ad for a pickup truck and not hear hear so many commercials bragging about “torque ratings.” It’s a critical aspect of counterbalance hinges too, as they generate torque to counter gravity’s force.

Below you’ll find an easy-to-follow guide to understanding torque and its role in a lid support hinge for heavy-duty applications. In no time, your lid will boast a safe, smooth open and close.

Understanding Torque

Before we go any further, let’s dig into exactly what torque is at a high level.

Torque is essentially a measure of rotational force that acts at a certain distance from an object’s pivot point. It’s expressed as the product of force and distance, giving us a clearer picture of how much twisting force a hinge experiences when a lid is moved.

In heavy-duty lid support hinges, understanding torque matters because it determines how effectively the hinge can support and balance the lid’s weight (more on this later). This, in turn, impacts the ease of motion and the stability of the lid when opened or closed, ensuring both functionality and safety in high-stress applications.

Why Torque Matters for a Lid Support Hinge

By knowing the torque of your lid, the counterbalance hinge your manufacturer designs will provide your desired action and balance. If the calculation is wrong, you’re at risk of selling a product that:

- Crashes on heads and fingers

- Doesn’t lift and close smoothly, giving off an aura of cheapness

- Floats in a half-up position, leaving it susceptible to wind or bumps from nearby folks

- Doesn’t provide a good seal

Overview: What Is Lid Torque?

Torque depends on the weight and size of your lid, door, or cover. Torque is defined as the lid’s weight multiplied by the distance from its center of gravity to the hinge axis.

Consider an industrial toolbox lid. Gravity induces a torque at the hinge axis that slams the lid closed or, at some angles, causes the lid to open further.

Consider an industrial toolbox lid. Gravity induces a torque at the hinge axis that slams the lid closed or, at some angles, causes the lid to open further.

Let’s pretend we have a solid aluminum lid that’s:

- 32” wide

- 24” deep

- 1” thick

- 75 pounds

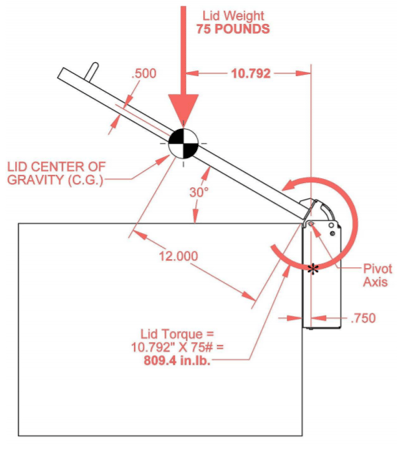

The lid’s center of gravity would be in its geometric center, 0.5” up from the bottom surface and 12” away from the back edge. Remember, the pivot axis is an additional 0.75” beyond the back edge and on the same plane as the bottom of the lid.

When this lid is closed (0° open), the center of gravity is a horizontal distance of 12.75” from the hinge pivot axis and a vertical distance of +0.5” from the axis. This means the lid torque in the closed position will be 12.75 in. x 75 lbs., which comes out to 956.25 in.-lbs.

This will be the largest torque for this lid design. The torque will decrease as the lid is opened, as you’ll see below in the diagram.

Note that in this example, the center of balance is above the hinge pivot axis, so the vertical distance is positive. If the center were below the axis, the vertical distance would be negative.

Other Numbers That Matter

Once the design engineers get all the data they need, they can develop the perfect counterbalance. The more information they get, the quicker the design process can go.

Start by finding these measurements. If you don’t know how to find them, your counterbalance hinge manufacturer should be able to help:

- Center of Gravity: The specific point on an object where the mass is evenly distributed and about which the object can rotate in equilibrium.

- Balance Angle: The angle at which a lid or cover stays open without additional support, reflecting its equilibrium state.

- Balance Point: The position where the lid remains stable and does not move either toward closing or opening further.

- Lid Weight: The total weight of the lid, which influences the required torque for balance and ease of motion.

You can learn more about these measurements here. With the right numbers, you’ll get a lid that’s smooth and safe rather than floaty or crashy!

Additional ResourcesTo see more about lid torque and counterbalancing, check out the Vectis DYO App, which allows engineers to design their own counterbalance right in their web browser. Once you provide your data, the Vectis App plots the lid torque at all angles -- a handy reference for defining the counterbalance hinge you want. With the lid torque defined, you can adjust the app’s other parameters as needed. Curious to learn more about selecting the correct heavy-duy lid support hinge? Check out our other guide: Choosing a Heavy-Duty Lid Support Hinge | Quick Reference Guide |

Lid Support Hinges & Torque: FAQS

How Do Different Materials Used in Lid Hinges Affect the Torque Requirements?

Different materials in lid hinges affect torque requirements due to their distinct physical properties such as strength, flexibility, and weight. Materials like steel might offer higher durability and support heavier lids, thus requiring different torque specifications compared to lighter materials like aluminum. Understanding these differences is crucial for designing effective heavy-duty lid supports that meet specific operational and safety standards.

What Are the Safety Implications of Incorrectly Calculating the Torque for a Heavy-Duty Lid?

Incorrectly calculating the torque needed for a heavy-duty lid can lead to several safety issues. If the torque is underestimated, the lid may close unexpectedly, posing a risk of injury. Conversely, overestimating torque could result in difficulty in opening the lid, potentially leading to ergonomic strains or accidents. Proper torque calculation ensures the lid operates smoothly and safely.

Can the Principles of Torque and Lid Support Discussed Be Applied to Other Types of Mechanical Supports or Hinges?

Yes, the principles of torque and lid support can be generalized to other mechanical supports and hinges. Understanding how torque influences the movement and stability of a lid can be applied to designing better door hinges, automotive hatches, or even adjustable furniture parts. These principles help in creating more efficient and safer mechanical designs across various applications.

Covering All the Bases for Your Lid Support Hinge

There are other design factors you should relay your motion control design team to ensure a successful project and that you’re getting a lid support hinge that can stand up to the rigors of application.

The best way to do that? Speak with an engineer directly, which you can do by clicking below.

.png?width=12000&height=2033&name=WeberKnappLogo_white%20(1).png)