Editor's Note: This piece is an installment of an occasional series that looks at metalworking and fabrication services offered by Weber Knapp.

When creating a finished piece of any nature, what's one of the most important elements in its fabrication?

Precision.

Even a discrepancy of fractions of a millimeter can make the difference between something that fits and works perfectly versus something that's useless.

A metalworking method with precision in its DNA, CNC (Computer Numerical Control) turning allows for fabricating finished pieces that meet a project’s exact specifications.

In this article, we'll take a look at CNC turning services, examining:

- What is CNC turning?

- The metal fabrication method's benefits

- Our CNC turning services

- The CNC turning FAQs we regularly field

What is CNC Turning? An Overview + 7 Benefits

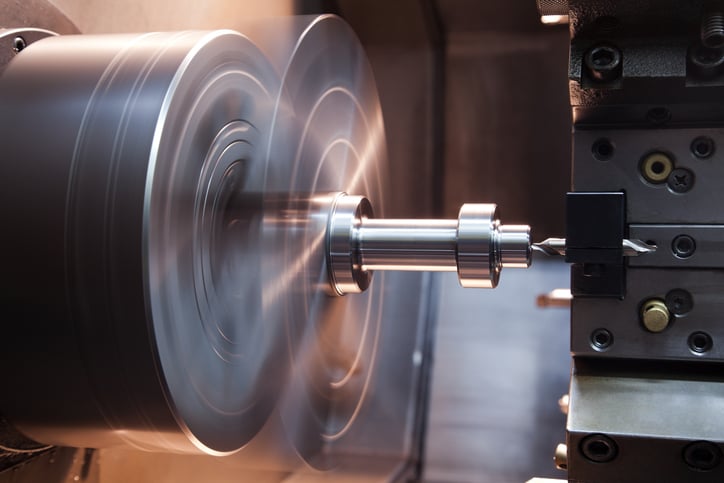

CNC turning is a sophisticated manufacturing process that uses computer-controlled lathes to shape materials into precise components.

Unlike traditional lathes, which require manual operation by skilled machinists, CNC lathes automate the cutting process under computer guidance, executing predefined programs to produce parts with intricate geometries and tight tolerances.

The CNC turning process begins with a detailed design of the part to be produced, typically created using CAD (Computer-Aided Design) software. This design is then translated into a CAM (Computer-Aided Manufacturing) program, which generates the necessary machine code (G-code) to instruct the CNC lathe on producing the part. This code specifies everything from tool paths to speeds, feeds, and depth of cuts.

Once the machine setup is complete and the program loaded, the machining process can begin. The workpiece is spun at high speed, and the cutting tool is brought into contact with the material. As the workpiece rotates, the tool is moved along various axes (typically two or three, depending on the complexity of the machine and the piece being manufactured) to make precise cuts, removing material to shape the part according to the specifications set out in the program.

CNC turning and milling services are used to create a wide variety of finished pieces, including:

- Shafts

- Axles

- Bushings and bearings

- Bolts

- Screws

- Fasteners

- Rivets

7 Benefits of CNC Turning Services for Your Project

In creating finished components from stock metal, why choose CNC turning as opposed to other types of fabrication?

That's easy. CNC turning services offer these seven benefits that most other fabrication processes can't match:

- Precision and Accuracy

- Efficiency and Speed

- Versatility

- Repeatability

- Cost-Effectiveness

- Complexity and Design Freedom

- Improved Safety

1. Precision and Accuracy

CNC turning machines are highly accurate and capable of producing parts with extremely tight tolerances – typically working within tolerances of +/- 0.005 inches or better. That's significantly better than manual machining methods, which can have tolerances in the range of +/- 0.25 inches. The computerized control ensures that each part is produced exactly to specification, minimizing the risk of human error.

2. Efficiency and Speed

CNC turning centers are designed for rapid production, allowing for the fast turnaround of parts. Automating the CNC process means that parts can be produced more quickly than manual machining methods, making it ideal for both prototyping and mass production.

3. Versatility

CNC turning can work with a wide range of materials, from metals such as aluminum and steel to plastics and composites. This flexibility allows manufacturers to produce parts for a diverse set of industries and applications.

4. Repeatability

The computer-controlled process ensures that each part is produced with identical dimensions, which is critical for large-scale production runs where consistency and quality control are paramount.

5. Cost-Effectiveness

Although the initial setup cost for CNC turning might be higher than manual machining, the efficiency and speed of production lead to lower costs per unit, especially in high-volume production. Automated operations also reduce labor costs and the potential for errors, further contributing to cost savings.

6. Complexity and Design Freedom

CNC turning machines can produce complex shapes that would be difficult or impossible to achieve with manual machining. The precision of CNC technology also allows for the incorporation of intricate details and features into designs without compromising accuracy.

7. Improved Safety

The automated nature of CNC turning reduces the risk of accidents and injuries associated with manual machining. Operators do not need to be near the cutting tools, as the machines are enclosed and operated remotely.

CNC Turning Service Vs. 3D Printing

A newer method of metal fabrication, 3D metal printing is an alternative to CNC turning. While 3D printing does represent a big leap in technology for manufacturing, it has its drawbacks when compared to CNC turning services:

- CNC turning produces parts from solid materials, which often results in stronger and more durable components than those made through 3D printing. The latter builds items layer by layer, which might lead to weaker spots due to the bonding between layers.

- For projects requiring high precision and tight tolerances, CNC turning is typically the better choice as it can handle working within the range limit in a way that 3D printers can't.

- CNC turning generally delivers a superior surface finish right off the machine, with parts often ready for use or requiring minimal finishing. In contrast, 3D printed parts may need additional post-processing steps, like sanding or chemical treatments, to smooth out the layer lines and achieve a comparable finish.

CNC Turning Services Vs. Laser Cutters

Another metal fabrication method CNC turning services are often considered against, laser cutters also leverage some of the latest technology to create extremely precise finished pieces. And like with 3D printing, CNC turning does have some advantages against laser cutting that are hard to ignore:

- CNC turning excels in creating high-precision cylindrical and complex parts, ideal for components requiring exact concentricity.

- Suitable for continuous production, CNC turning is optimal for large orders that demand uniformity and exact specifications.

- Capable of handling a diverse range of material types and thicknesses, CNC turning offers more flexibility compared to laser cutting.

- Preferred in applications where mechanical strength and robustness matter, CNC turning is a better choice for durable component manufacturing.

CNC Turning Services at Weber Knapp: Equipment

Like all of our machining and metalworking capabilities, we use CNC turning in manufacturing many of our own products. Across all of our product lines, we'll put our lathes to work fabricating our screws and rivets or anything we need that can be made from turning down bar stock.

A Look at Our CNC Turning MachinesOn our shop floor, we have six CNC turning machines that are regularly put to use:

|

CNC Turning Services for Your Project With Weber Knapp

There's nothing we love more than completing an order for a client and having the entire project run like a well-oiled machine.

- Deadline: This one is pretty self-explanatory – when do you need your order completed? Your timeframe affects everything we'll do to meet your expectations.

- What you are looking to have made. This goes beyond the macro level, e.g. saying you need rivets made. The more details you can give us, especially in early conversations, the better. We'll need information such as:

- Part thickness and dimensions

- Material type and grade

- Tolerances

- In our eyes, there's no such thing as too much information

- Order size: What follows knowing what we're fabricating for you is how much of that something are we making.

- Post-processing: Is there any additional work you'd like us to complete for your finished pieces?

Frequently Asked Questions About CNC Turning Services

What Limitations Do You Have in Your CNC Turning Capabilities?

That comes down to our machines and their maximum stock diameters.

Our Citizen L20s can turn parts up to 0.75" in diameter.

Our Tsugami BO326-II can turn parts up to 1.25” in diameter.

The Okuma GENOS can turn bar stock up to 2.5” in diameter.

What Materials Are You Able to Turn?

We're able to machine a variety of materials, including:

- Steel- 1215, C1018

- Stainless Steel - 303, 416

- Plastic – Delrin (Acetal), Nylon 6/6

- Brass – Alloy 360

- Bronze – 544, 954

- Aluminum - 6061

How Soon Can I Get Started?

That's entirely up to you! We're ready to start work on your project when you are. Get in touch with us today:

.png?width=12000&height=2033&name=WeberKnappLogo_white%20(1).png)