Using laser cutting machines to produce detailed metal parts has been common practice since the early 1970s. In today’s manufacturing environment, laser cutters are widely used because CAD-driven designs can move from file to finished part in minutes.Not all laser cutting machines perform the same way.

The most common types of lasers include CO2 and microjet systems, but fiber lasers continue to gain traction as manufacturers look for greater precision and flexibility in metal cutting.

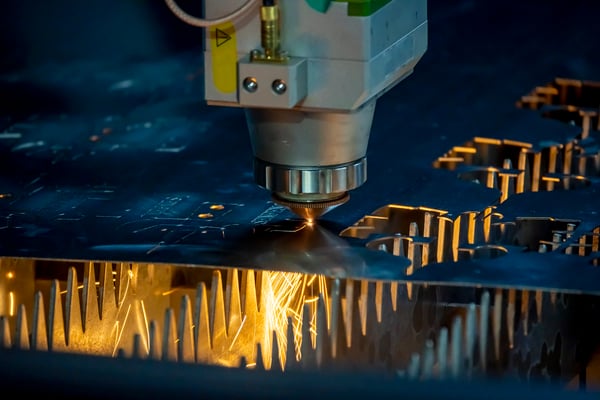

CNC fiber laser cutting machines bring a different approach to metal processing, addressing many of the limitations found in traditional laser systems used on the shop floor.

Why Use a CNC Fiber Laser Cutting Machine?

A fiber laser cutter offers more versatility and ease-of-use than other laser cutting machines, so it’s ideal for many machining purposes.

Some of the benefits of a fiber laser cutting machine include:

- The ability to cut reflective material

- A spot size 100x smaller than that of a CO2 laser

- Extremely focused and flexible

- Cleaner edges and faster cutting speeds

- Easier to use for producing detailed cuttings

But how does a fiber laser cutting machine work, you ask? How different is it from a CO2 laser or a microjet laser cutter?

How Does a Fiber Laser Cutting Machine Work?

A fiber laser operates a bit differently than other lasers used in metal cutting, but it also offers more precision and a higher-quality finished product.

A CO2 laser utilizes a beam passed through a gas mixture or manipulated by radio frequency energy. Power source, gas flow, and erosion are all common issues that affect the efficiency of a CO2 laser. Microjet lasers have similar problems, but instead of a gas mixture, they use a condensed stream of water to guide the laser.

The glass fiber transfers the light energy to the lenses where it is focused. This replaces the mirrors used in a CO2 laser. The distance between mirrors changes as the laser cutting head moves. This causes variation in cut quality depending on the laser cutting head location. Also, the mirrors can become misaligned or dirty. resulting in poor cut quality.

These issues don't exist on a fiber laser. Instead of using a gas or water, the fiber laser uses a solid gain medium, which eliminates the problem of gas flow and erosion.

What Can CNC Fiber Laser Cutting Machines Produce?

If you’re looking for a way to cut a complex design, chances are you want to use CNC fiber laser cutters. Using a laser cutter allows you to craft quality metal products out of a variety of materials, as seen below.

Outsourcing CNC Fiber Laser Cutting Services

CNC technology continues to evolve, and metal manufacturers have to constantly evaluate new machines to keep up. For example, at Weber Knapp, we have two CNC laser cutting machines:

- Prima LGf 4kW - fiber laser CNC cutting machine

- Prima Laser Platino - CO2 laser CNC machine

Outsourcing your CNC cutting needs allows you to decrease overhead and expensive equipment purchases while also getting a battle-tested engineering team.

Depending on the manufacturer, you may be able to bundle several machining capabilities include a single-source solution, including:

- Progressive die stamping

- CNC hydraulic press brakes

- CNC turning

- MIG robotic welding

- CNC routing

CNC Fiber Laser Cutting Machine FAQsThese are some of the questions that come up most often when manufacturers ask us about CNC fiber laser cutting. Q: What materials and thickness ranges are best suited for CNC fiber laser cutting?A: CNC fiber laser cutting is commonly used for metals such as stainless steel, carbon steel, aluminum, brass, and copper. Fiber lasers perform especially well with reflective materials that can be challenging for other laser types. Material thickness depends on laser power, material composition, and cut quality requirements. In many manufacturing environments, CNC fiber laser cutting is used for thin to medium-gauge metals where tight tolerances, clean edges, and repeatability matter most. Q: When does it make more sense to outsource CNC fiber laser cutting instead of bringing it in-house?A: Outsourcing CNC fiber laser cutting is often a practical choice when production volumes don’t justify the cost of equipment, maintenance, and specialized labor. It also allows manufacturers to stay flexible without committing to major capital investments. Outsourcing can be especially useful for projects with varying part designs, short lead times, or additional fabrication steps beyond cutting. Working with a single manufacturer that offers multiple machining capabilities can also simplify coordination across production stages. Q: How does CNC fiber laser cutting compare to other cutting methods for complex parts?A: CNC fiber laser cutting is well suited for complex geometries that require fine detail and consistent cut quality. Compared to plasma cutting, fiber lasers typically produce tighter tolerances and cleaner edges, reducing the need for secondary finishing. When compared to processes such as waterjet cutting or stamping, CNC fiber laser cutting offers advantages in speed and precision for certain materials and part designs. The most effective method depends on material thickness, production volume, and the level of detail required for the finished part. |

CNC Fiber Laser Cutting Machines in Modern Manufacturing

CNC fiber laser cutting machines support the growing demand for precise, repeatable metal part production. Their ability to manage intricate designs and tight tolerances makes them a strong fit for modern manufacturing environments.

For teams evaluating production methods, CNC fiber laser cutting offers a balance of accuracy, efficiency, and material flexibility. Understanding where these machines perform best helps manufacturers plan smarter workflows and adapt as project requirements continue to change.

Ask an Engineer

If you have questions about CNC machining or want to discuss whether CNC fiber laser cutting is the right approach for your project, you can contact a Weber Knapp engineer directly.

This article was originally published in June of 2020 and was recently updated to reflect current industry trends.

.png?width=12000&height=2033&name=WeberKnappLogo_white%20(1).png)