Say you have a design for a component, but you’re not quite sure how to make it. You know it should be die stamped, but you only have a traditional die stamping machine, and that’s not going to cut it for this complex design.

That’s where third-party machining partners come in handy. They’re skilled in various manufacturing operations, including progressive die stamping. Outsourcing to an expert saves you time and money vs. custom tooling a brand-new machine and learning how to use it.

But, how do you get quality progressive die stamping parts when you don’t have as much control over the process? Get ready, because we’re about to tell you.

What Is Progressive Die Stamping?

Traditional stamping machines can produce a part in a single operation. A ram descends on the workpiece, punching out a component in one hit.

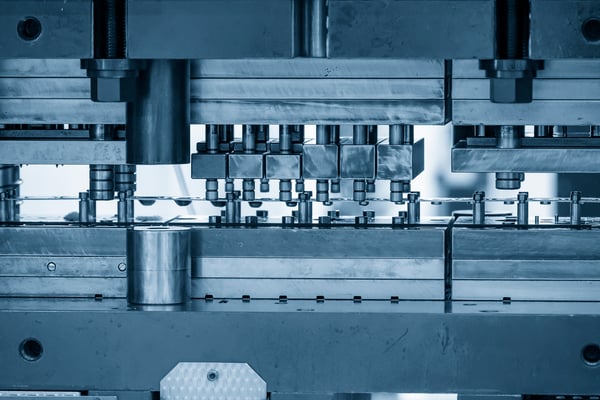

A progressive die stamping machine, on the other hand, produces a part in a series of operations. A feeding system pushes the metal coils through the various stations until the part is the exact shape you desired. These stations can handle a variety of operations, including:

- Bending

- Punching

- Coining

- Precision metal stamping.

The “progressive” part of progressive die stamping machines comes from the fact that the material has to progress through these stations in a certain order before the component is complete. Think of it like an assembly line, where one process is followed by another.

Considerations for Progressive Die Stamping Parts

While progressive die stamping might seem like a simple process, there’s a lot that goes into deciding the best way to make a part, and even whether progressive die stamping is the right option.

When considering a progessive die stamping machine job, engineers should consider:

- Shape

- Material

- Thickness and size

- Tooling and order volume

Shape Considerations

If the tolerances specified are too strict, the shape may not be manufacturable. Recommended tolerances are based on the form, width, and full size of the part shape.

The material comes into play here too. As you cut steel, for example, it can begin to sheer or break away at an angle. Most manufacturers aim for 30% sheer or less. To keep the hole at the necessary size, you may need to increase the clearance of the die block to reduce shearing.

A lot more goes into shape design than you might expect, but it’s worth it. Remember, measure twice, cut once!

Material Considerations

Materials commonly stamped include:

- Hot rolled steel

- Cold rolled steel

- Stainless steel

- Bronze

- Acetal plastic

- Nylon

- 260 brass (half hard)

Your material choice should depend on the function of the end product, and what kind of strength and resistances it will need. Don’t forget to consider the tooling’s material; some punches may be coated differently to hold up to the material being stamped.

Thickness & Size

Since everything from tiny fasteners to car hoods can be stamped, it really comes down to the size and tonnage capabilities of the manufacturer’s equipment. Different materials and thicknesses will require different applied forces.

At Weber Knapp, for example, our coil-fed automatic presses range from the accommodating 60-ton Minster No. 6 to the heavy-duty 300-Ton Minster E2-300-72-42, with other sizes in between. Our manually fed machines are equally as flexible.

Tooling & Volume

Tooling is mainly up to the manufacturer because certain tools need to be custom-made to fit the manufacturer’s presses. Volume, too, is important. Sometimes manufacturers have different practices for producing components for low volume versus high volume.

Outsourcing Your Progressive Die Stamping Services

With so many considerations at play for progressive die stamped parts, it might be worth outsourcing to an experienced manufacturer.

You can consolidate transportation costs and lead time by single-sourcing, so consider working with a full-service provider also skilled at:

- CNC fiber laser cutting

- CNC turning

- CNC press brake services

- CNC routing

- Robotic welding

But what’s even more important than machine capabilities? Engineering design to match it. Whether it’s in-house or out-of-house, make sure you have the engineering staff that’s able to meet your specific functionality needs before you fire up the machines.

Ask an engineer below to get a better idea of how you can do your part in ensuring your finished product meets expectations.

.png?width=12000&height=2033&name=WeberKnappLogo_white%20(1).png)